Sharif Strategic Systems Technology Company has obtained its knowledge-based certification since 2014 and has localized and produced many control and monitoring systems to date.

Due to extensive experience working with sensors and industrial devices, new-generation automation and smart solutions based on IoT have been part of the company’s services since 2017.

The company’s collaboration with both government and private organizations, as well as a diverse range of clients, has led to the execution of various projects in the field of IIoT (Industrial Internet of Things) to date. Among these projects are the monitoring and control of pipeline pressure in water transmission lines and remote reading of power plant sensors.

Why collaborate with the “Sharif Smart Solutions” division?

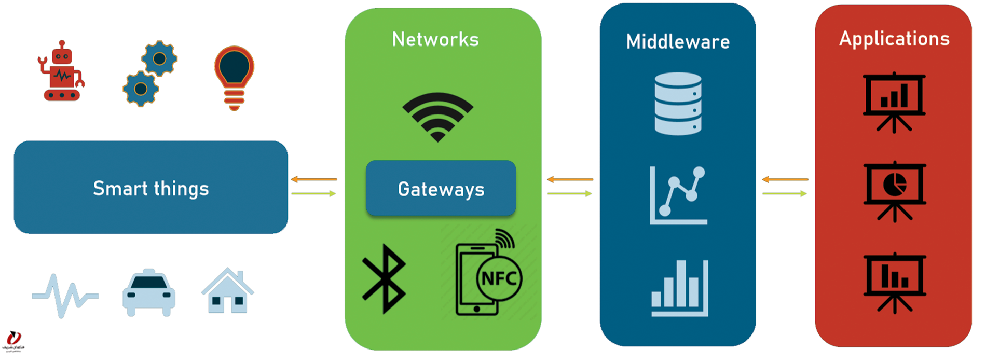

Industrial Internet of Things (IIoT) is essentially a specific application of IoT in the industrial and manufacturing sectors. It follows the same philosophy and involves a network of various devices connected through information and communication technologies, enabling monitoring, data collection, data exchange, and analysis.

What happens in IIoT is the connection of machines, smart devices, advanced data analytics, and workers in the workplace. This creates deep insights into processes, enabling more informed and quicker decision-making in business operations.

IoT solutions in industry lead to increased production, precision in quality and its monitoring, as well as enhanced safety for workers and machine operators. Today, Industrial Internet of Things is being implemented across various industrial sectors, demonstrating its growing importance and value. The applications of IIoT can generally be categorized into the following areas:

The primary focus in the field of IoT Devices is on equipment tracking and predictive (smart) maintenance. By installing various sensors on equipment, it is possible not only to track their location and status but also to detect potential failures in advance.

For example, by identifying corrosion in equipment, repairs can be made before a complete breakdown occurs. This helps reduce costs and enhance safety, as equipment failure can be highly hazardous.

The application of Internet of Things (IoT) in logistics primarily focuses on the precise organization and execution of complex operations.

Logistics, in general, refers to the precise coordination and execution of a complex operation. In the business domain, logistics is defined as the management of the flow of goods, services, and information between the point of origin and the point of consumption to meet customer or company needs.

The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as consumables like food and other essential items. Logistics management is a crucial part of supply chain management and engineering.

It involves planning, implementing, and controlling the efficient movement and storage of goods, services, and related information from the point of origin to the point of consumption to meet customer demands.

The complexities of logistics can be optimized using specialized simulation software, modeling, analysis, visualization, and process enhancement techniques.

The simplest definition of smart manufacturing operations is monitoring process efficiency and automatically adjusting equipment. A broader definition of smart manufacturing encompasses a wide range of advanced technologies.

Some key technologies in smart manufacturing and IoT include big data processing capabilities, industrial equipment connectivity, and advanced robotics.

With smart manufacturing operations, it is possible to enable automated machine loading, safe human-robot interaction, and real-time product quality monitoring. Additionally, production control processes can be implemented based on QRM (Quick Response Manufacturing) technologies.

Other objectives may include rapid adjustments in production levels based on demand, supply chain optimization, efficient manufacturing, and recyclability.

A smart grid represents a comprehensive set of current and proposed responses to the challenges of power supply.

Due to a wide range of factors, there are multiple competing classifications, and no universal definition exists. However, a smart grid can generally be defined as an electrical network that integrates various energy operations and actions, including smart meters, smart appliances, renewable energy sources, and energy-efficient resources.

Electronic climate control, power generation, and distribution management are key aspects of a smart grid. Although the term is commonly used in the context of technical infrastructure, the expansion of smart grid technology signifies a fundamental reengineering of the power service industry.

In addition to the mentioned benefits and applications, remote access and management are key advantages of IIoT.

By establishing a communication infrastructure, not only can these objectives be achieved, but also data collection, integration, and the application of data science and machine learning can enable the development of predictive models and virtual system equivalents, known as digital twins.

تمامی حقوق برای شرکت فناوران شریف محفوظ است.